Demolition Robotics: Transforming the Industry: 11xplay pro, Diamondexch9, Sky exchange bet

11xplay pro, diamondexch9, sky exchange bet: Demolition Robotics: Transforming the Industry

Have you ever watched a demolition crew tear down a building using heavy machinery and thought, “There must be a better way to do this”? Well, you’re not alone. The demolition industry has been revolutionized in recent years by the introduction of demolition robotics. These advanced machines are changing the game when it comes to tearing down structures quickly, efficiently, and safely.

Gone are the days when demolition crews had to rely solely on manual labor and heavy equipment to bring down buildings. With the advent of demolition robotics, the industry has seen a significant shift towards automation and technology-driven solutions. These robotic machines are equipped with cutting-edge tools and software that enable them to demolish structures with precision and speed.

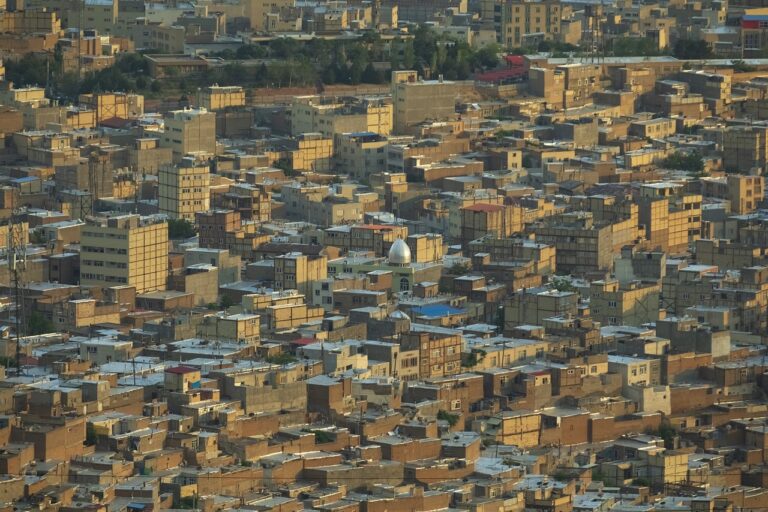

One of the primary advantages of demolition robotics is their ability to access hard-to-reach areas that traditional machinery and workers may struggle to reach. These machines can navigate tight spaces and complex structures with ease, making them ideal for urban environments where space is limited. In addition, demolition robots are equipped with sensors and cameras that allow operators to monitor the demolition process remotely, ensuring safety and efficiency.

Another key benefit of demolition robotics is their cost-effectiveness. While the initial investment in these machines may be higher than traditional demolition equipment, their long-term savings are considerable. By reducing the need for manual labor and minimizing the risk of accidents, demolition robots can help companies save time and money on demolition projects.

The versatility of demolition robotics is also worth noting. These machines can be customized to suit the specific needs of each project, whether it involves tearing down a small building or a massive industrial complex. With a wide range of attachments and accessories available, demolition robots can handle various tasks, from crushing concrete to dismantling steel structures.

As the demand for more sustainable and efficient demolition methods grows, the adoption of demolition robotics is expected to increase. Companies in the construction and demolition industry are recognizing the benefits of these advanced machines and are investing in them to stay competitive in the market. With ongoing technological advancements and innovations in robotics, the future of demolition looks brighter than ever.

In conclusion, demolition robotics are transforming the industry by providing safer, more efficient, and cost-effective demolition solutions. These machines are revolutionizing the way buildings are torn down, offering a glimpse into a future where automation and technology play a significant role in construction and demolition processes. As more companies embrace this cutting-edge technology, the possibilities for innovation in the demolition industry are endless.

FAQs:

Q: Are demolition robots safe to use?

A: Yes, demolition robots are equipped with sensors and cameras that allow operators to monitor the demolition process remotely, ensuring safety and efficiency.

Q: How much do demolition robots cost?

A: The cost of demolition robots can vary depending on the size, capabilities, and accessories of the machine. However, the long-term savings and benefits of using these machines are considerable.

Q: Can demolition robots handle different types of structures?

A: Yes, demolition robots can be customized with various attachments and accessories to handle different types of structures, from small buildings to large industrial complexes.

Q: Are demolition robots environmentally friendly?

A: Yes, demolition robots are designed to minimize waste and reduce the environmental impact of demolition projects by using precise and controlled demolition methods.